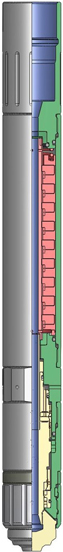

Removing mineral scale is an essential part of the well intervention process, but a single misstep can damage hard-to-reach equipment and well components miles below the surface, sometimes leading to abandonment. The Tempress JetRotor tool removes mineral scale safely and quickly to stimulate well completions without damaging production tubing or downhole equipment.

The JetRotor tool is compatible with a broad range of fluids making it applicable in almost all coiled tubing well service jobs. The design is highly compact, which greatly simplifies transport, BHA make-up and job execution.

The patented open-flow seal design virtually eliminates power losses due to leakage and friction. This seal design ensures that maximum hydraulic power is delivered to the jets.

High-Pressure, High-Power Jets

Operates at the highest power and pressure levels available in the industry

High-Temperature

Routinely used in severe 400°F/200°C sour gas environments

Corrosion-Resistant Alloy Construction

Fully acid capable — delivers uniform acid blast

Can run on energized fluids including nitrogen and carbon dioxide

Available Sizes:

1.69 in. (43 mm)

2.06 in. (52 mm)

2.12 in. (54 mm).